English

English  Español

Español Português

Português русский

русский Français

Français 日本語

日本語 Deutsch

Deutsch tiếng Việt

tiếng Việt Italiano

Italiano Nederlands

Nederlands ภาษาไทย

ภาษาไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা ভাষার

বাংলা ভাষার Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türkçe

Türkçe Gaeilge

Gaeilge العربية

العربية Indonesia

Indonesia Norsk

Norsk تمل

تمل český

český ελληνικά

ελληνικά український

український Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақша

Қазақша Euskal

Euskal Azərbaycan

Azərbaycan Slovenský jazyk

Slovenský jazyk Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Srpski језик

Srpski језик

Industry News

Selection points of screw chiller

When purchasing a screw chiller, it is necessary to fully consider that the cooling capacity matches the needs of the place of use, the working environment is suitable for air cooling or water cooling, the type of refrigerant meets the requirements and needs of environmental protection, and the bran......

Read MoreSelection factors and customer cases of chillers used in pharmaceutical and chemical workshops and computer rooms

The selection of chillers used in pharmaceutical and chemical workshops, computer rooms and other working environments needs to consider many factors, including temperature control requirements, cooling capacity requirements, energy consumption, noise, maintenance and maintenance, quality and brand ......

Read MoreSelection and application of laboratory chiller in cathode material of energy storage industry

In the positive electrode material laboratory of the energy storage industry, the selection of the laboratory chiller is a very important step. Before determining the selection, it is necessary to consider the cooling requirements of the laboratory, environmental factors, selection brand, performanc......

Read MoreReasons and solutions for poor cooling effect of industrial chillers

Industrial chillers are assembled from multiple machines and equipment such as condensers, evaporators, and compressors. The reasons for the poor cooling effect of industrial chillers include cooling system failure, unreasonable cooling system design, and poor circulating water quality. The normal o......

Read MoreReasons and solutions for industrial chillers not cooling

The reason why the industrial chiller does not cool may be due to insufficient refrigerant, dirt in the condenser, improper position of the slide valve, leakage of cold air, fouling of the evaporator, and so on. The high-pressure alarm failure may be caused by frequent start and stop of the chille......

Read MoreIs it better to choose air-cooled or water-cooled chiller?

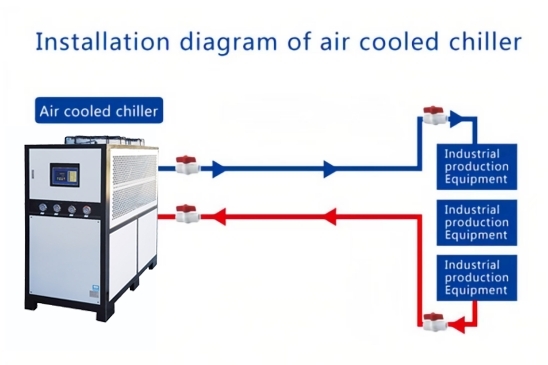

With the increasing application of industrial chillers, such as: plastic industry, petrochemical industry, electronics industry, vacuum coating, etc. will use industrial chillers. Its applicable places have increased, and the specifications and models of manufacturers and chillers are also increasin......

Read More