English

English  Español

Español Português

Português русский

русский Français

Français 日本語

日本語 Deutsch

Deutsch tiếng Việt

tiếng Việt Italiano

Italiano Nederlands

Nederlands ภาษาไทย

ภาษาไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা ভাষার

বাংলা ভাষার Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türkçe

Türkçe Gaeilge

Gaeilge العربية

العربية Indonesia

Indonesia Norsk

Norsk تمل

تمل český

český ελληνικά

ελληνικά український

український Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақша

Қазақша Euskal

Euskal Azərbaycan

Azərbaycan Slovenský jazyk

Slovenský jazyk Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Srpski језик

Srpski језик

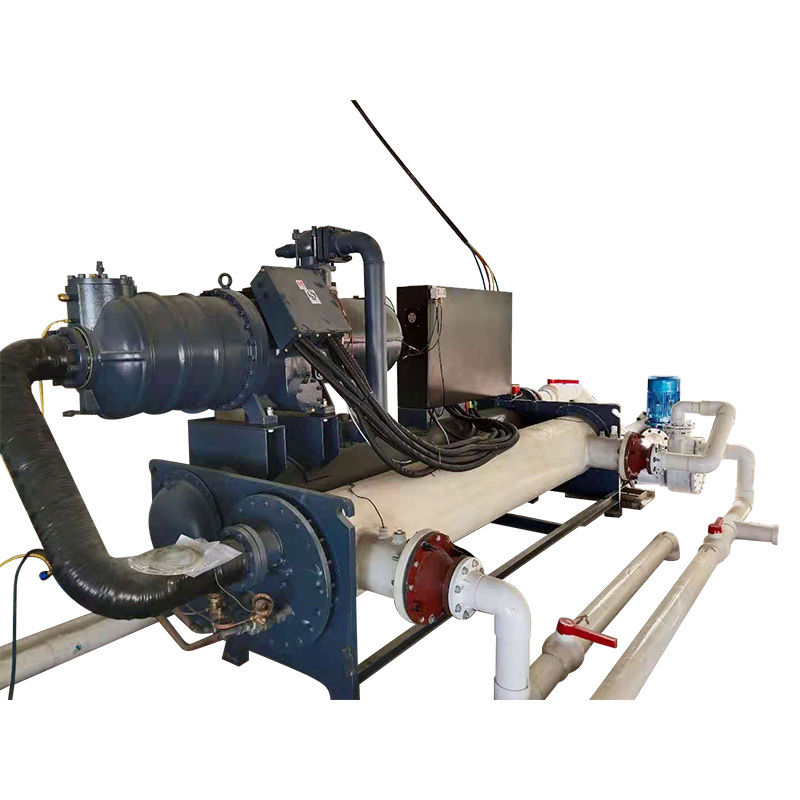

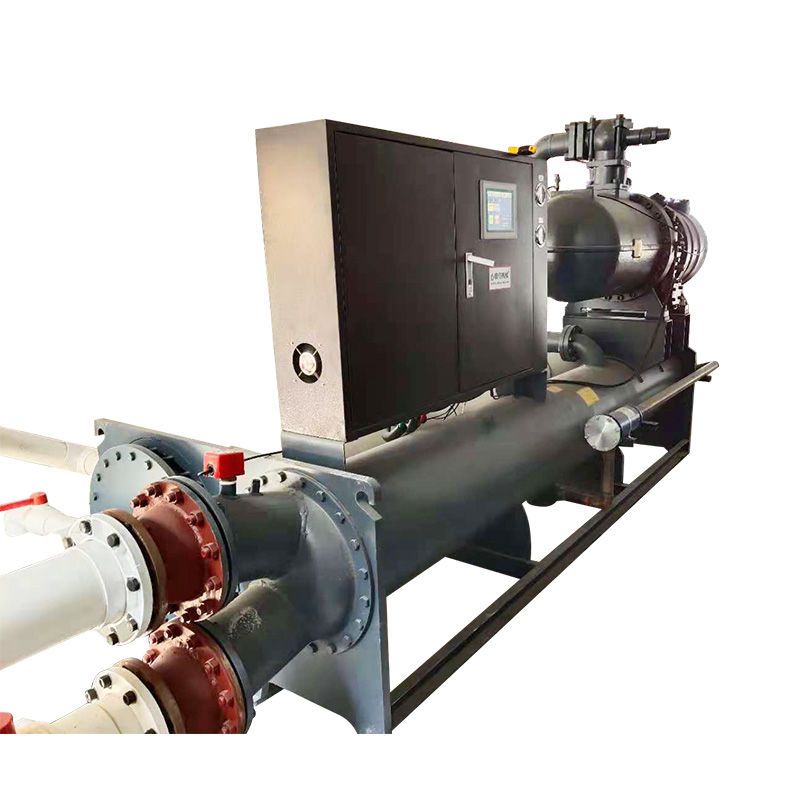

200HP Water-cooled Screw Chiller

200hp Water-cooled Screw Chiller is a CE-certified chiller with screw chillers to this name because of a screw compressor. Its refrigeration power is larger than the power of the scroll, mainly used in chemical plants, ink printing plants, automotive manufacturers, or central air conditioning systems or other large industrial cooling. Since the source of heat exchange is water, there is a dedicated cooling tower equipped, so it is called "water cooling".

Model:SLLG-200

Send Inquiry

200hp Water-cooled Screw Chiller

Introduction

200hp Water-cooled Screw Chiller is a CE-certified chiller with screw chillers to this name because of a screw compressor. Its refrigeration power is larger than the power of the scroll, mainly used in chemical plants, ink printing plants, automotive manufacturers, or central air conditioning systems or other large industrial cooling. Since the source of heat exchange is water, there is a dedicated cooling tower equipped, so it is called "water cooling".

Screw chillers can be divided into two types: water-cooled screw chillers and air-cooled screw chillers. Because of their key components-the compressor adopts screw type, it is named screw chiller. The unit is in the state of gas coming out of the evaporator. Refrigerant: After adiabatic compression by the compressor, it becomes a high temperature and high pressure state.

The compressed gas refrigerant is cooled and condensed at equal pressure in the condenser, and then changes into a liquid refrigerant after condensation, and then expands to a low pressure through a throttle valve and becomes a gas-liquid mixture. Among them, the liquid refrigerant under low temperature and low pressure absorbs the heat of the substance to be cooled in the evaporator and becomes a gaseous refrigerant again.

The gaseous refrigerant re-enters the compressor through the pipeline to start a new cycle. These are the four processes of the refrigeration cycle and the main working principle of the screw chiller.

Non-standard type can be customized for ultra-low temperature -50°C. This chiller is popular with customers and is affordable. It is generally used for cooling plastic molds. The machine runs continuously for 4,800 hours without failure.

The whole machine has a 1-year warranty and free technical guide services for more than 10 years. The customized high-efficiency energy-saving system can save energy by 13% compared with ordinary chillers and reduce production costs. Create real value for customers to improve production efficiency.

Model: SLLG-200

Brand: Jiusheng

Minimum order quantity: 1

Payment method: wire transfer, exw, fob / negotiation

Price: negotiation

Origin: Dongguan, Guangdong, China

Certificate: CE

Delivery time: 10-30 days / negotiation

Service: OEM / ODM

Supply Ability: 100PCS / Month

Packing: plywood packaging

Features

1. High-precision temperature control; high-speed cooling efficiency; energy-saving and environment friendly operation.

2. World-renowned accessories: Panasonic/Daikin/Copeland compressors, Schneider Electric, Muchuan water pumps, Talos copper pipes, etc.

3. High-performance, high-flow special pump;

4. Streamlined aesthetic design, concave-convex design of the operation panel (humanized design), the operation procedure is clear at a glance;

5. Compared with the traditional control method, this special controller has obvious advantages such as anti-electromagnetic interference, anti-cold, anti-heat, strong control logic, sensitive response and accurate action.

6. Comprehensive safety protection: 1) High and low pressure protection and safety valve of the refrigeration system; 2) Soft and hard double protection of compressor overload; 3) Phase loss, reverse, undervoltage and overvoltage protection of the power supply; 4) Water system Freeze protection and water flow protection.

Parameters

| Model | SLLG-30 | SLLG-40 | SLLG-50 | SLLG-60 | SLLG-70 | SLLG-80 | SLLG-90 | SLLG-100 | SLLG-120 | |

| Cooling capacity | Kcal/h*103; | 88 | 119 | 148 | 170 | 199 | 228 | 268 | 284 | 335 |

| KW | 102 | 138 | 172 | 198 | 231 | 265 | 312 | 330 | 390 | |

| USRT | 29 | 39 | 49 | 56 | 66 | 75 | 89 | 94 | 111 | |

| power supply | 3PH-380V-50HZ | |||||||||

| Selection of refrigerant | R22/R407C/R134a0ptional | |||||||||

| Reflection | 1 in 1 out | |||||||||

| Throttling device | Thermal Expansion Valve/Electronic Expansion Valve | |||||||||

| coirf)ressor | Type | Semi-closed screw type | ||||||||

| Start method | Y - A/Split winding | |||||||||

| Energy control | 33%-66%-100% | 25%-50%-75%-100% | ||||||||

| Input power (KW) | 23.3 | 30.7 | 38.5 | 42.2 | 48.5 | 56.0 | 63.0 | 66.3 | 79.6 | |

| Rated current (A) | 39 | 52 | 65 | 71 | 86 | 94 | 106 | 111 | 134 | |

| Condenser | Type | High-performance externally threaded copper tube and tube type | ||||||||

| Water flow (m3/h) | 21.5 | 29.0 | 36.2 | 41.3 | 48. 1 | 55.2 | 64.5 | 68.2 | 80.8 | |

| Water pressure loss (Kpa) | 40 | 40 | 40 | 40 | 45 | 45 | 50 | 50 | 50 | |

| Water pipe specifications | DN65 | DN80 | DN80 | DN80 | DN80 | DN80 | DN100 | DN100 | DN100 | |

| Evaporator | Type | High-performance internally threaded copper tube shell and tube type | ||||||||

| Water flow (m3/h) | 17.5 | 23.7 | 29.6 | 34.0 | 39.7 | 45.6 | 53.7 | 56.7 | 67. 1 | |

| Water pressure loss (Kpa) | 60 | 60 | 60 | 60 | 60 | 60 | 65 | 65 | 65 | |

| Water pipe specifications | DN65 | DN80 | DN80 | DN80 | DN80 | DN80 | DN100 | DN100 | DN100 | |

| safety devices | Leakage switch safety device | |||||||||

| Noise (DB) | 55.0 | 55.6 | 56.5 | 59.7 | 60.2 | 60.4 | 60.8 | 61.0 | 63.8 | |

| Mechanical Dimensions | L:(mm) | 2000 | 2200 | 2400 | 2600 | 3000 | 3000 | 3000 | 3000 | 3100 |

| W:(mm) | 750 | 750 | 850 | 850 | 900 | 900 | 1000 | 1000 | 1100 | |

| H:(mm) | 1550 | 1550 | 1600 | 1600 | 1750 | 1750 | 1800 | 1800 | 1900 | |

| Machine weight (kg) | 960 | 990 | 1260 | 1380 | 1450 | 1520 | 1650 | 1750 | 1950 | |

| Run weight (kg) | 1100 | 1150 | 1420 | 1550 | 1650 | 1700 | 1830 | 1950 | 2150 | |

FAQ

Q1: Are you a manufacturer?

A1: Yes, we have more than 20 years of experience in chiller manufacturing. We are located in Renzhou Industrial Zone, Shatian Town, Dongguan City, Guangdong Province, China. Welcome to visit anytime!

Q2: Can you help us recommend a model suitable for our project?

A2: Yes, we have engineers professionally calculate for you and reasonably recommend the machine suitable for your use. Our engineers can check the details and make the structure. Based on the following points: 1) cooling capacity; 2) refrigerant; 3) cold water inlet and outlet temperature 4) voltage; 5) what industry 6) architectural drawings (if any) 7) other special requirements.

Q3: How to ensure that your products are of good quality?

A3: We use international brand accessories, such as Japan's Panasonic brand, American Copeland, Japan Daikin, French Schneider Electric Emerson expansion valve, etc. All products are tested under load to ensure good quality and easy installation.

Q4: How long is the warranty period?

A4: Counting from the date of production and leaving the factory, the free warranty is within 1 year. If both parties confirm that the quality causes the damage, a 12-month free warranty will be provided.

Q5: What is your payment method?

A5: We accept TT, LC, Western Union money transfer. Wire transfer and other methods, 50% deposit in advance for production, and the balance is paid before delivery.

Q6: Can you design for us?

A6: Yes, we can customize the production of chillers according to the user's detailed information. In addition, we can design the cooling circulation system (machine color appearance, cooling tower water pump, water tank water pump, closed evaporator). We can customize it for user needs.

Q7: What is the delivery time for production?

A7: For standard box-type chillers, 2HP-30HP is basically available in stock and can be shipped within 2 days after receipt. The production cycle of customized machines with special requirements such as non-standard voltage, refrigerant, internal structure, etc. is measured and determined according to the quantity. For screw chillers and scroll chillers, the production cycle is generally 25 working days after receiving the deposit.

Why buy a chiller from us?

A. Leading manufacturer of industrial chillers for 20 years.

B. Expert in industrial cooling solutions.

C. Many customized services can be provided for industrial chillers.

D. Stable quality + fast delivery time + reasonable price + strong technical support + intimate after-sales service.

E. Our industrial chillers have passed CE certification.

Applications

Thank you for your patience!

If you need to inquire about prices and technical issues, please call 13925748878 Miss Zhu,We will provide you with the best quality service.